Tel

Tel Email

EmailOverview of Polyester Sewing Thread and Nylon Sewing Thread

Release time:2025-02-28 Click:1874

Definition of Sewing Thread

Sewing thread, used in sewing machines

to stitch various fabric products. Industrial sewing threads are predominantly

polyester-based.

Types, Specifications and Applications

of Sewing Thread

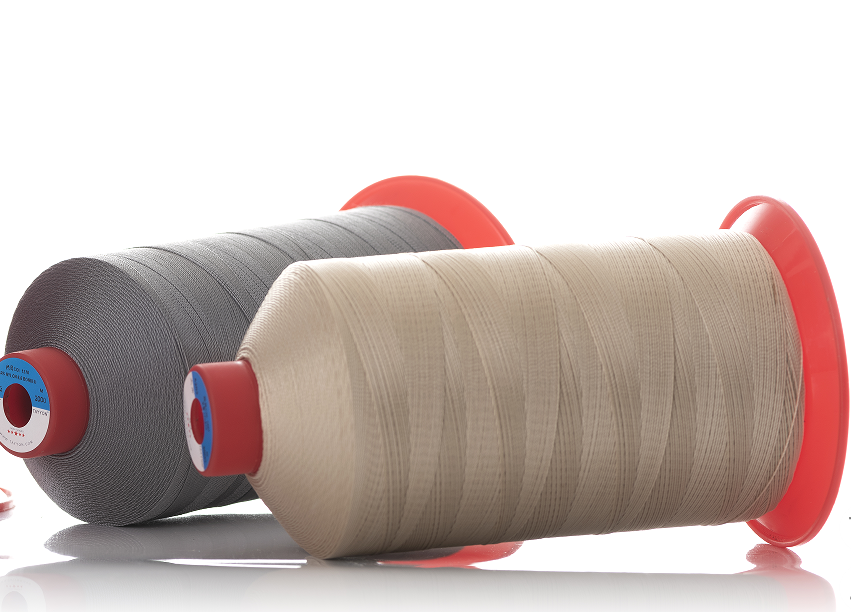

1. Synthetic Fiber Sewing Thread

Are the most commonly used type of

sewing threads in the current market, have two main kinds: polyester sewing threads and nylon sewing threads. Polyester sewing threads are further

categorized into: filament polyester

sewing thread and spun polyester sewing thread.

2. Filament

Polyester Sewing Thread

Also called high tenacity sewing thread,

charactered by high tenacity, wear resistance, bright and good color fastness,

but stiff and low elasticity.

3. Spun Polyester Sewing Thread

Charactered by soft, cost-effective

and easy to sew, but prone to pilling and lower tensile strength.

4. Nylon Sewing Thread

Also called #polyamide sewing thread,

twisted from 100% nylon filament, offers higher tenacity and elasticity, good

abrasion resistance, ideal for stretchable fabrics but costly. Tayyon always

only make nylon 6.6 sewing thread, few of nylon 6.

5. Bonded Thread

There are Bonded nylon thread and bonded

polyester thread, reinforced with low-melting-point fiber inside multi-ply

yarns during twisting, the fiber is melted to bond multi-ply yarns after heat

set, Tayyon is using this inner bond technology. Bonded thread is charactered by high tenacity, heat-resistant,

abrasion-resistant and multi-ply thread not loosening, it is suitable for thick

fabric materials or premium leather products.

6. Natural Fiber Sewing Thread

100% Cotton

Thread, made from pure natural cotton, charactered by heat-resistant and

compatible with cotton fabrics, but weaker in strength, elasticity and

durability, and costly..

7. Blended Sewing Thread

There are poly-poly

core spun sewing thread and cotton-poly core spun sewing thread, reinforced with

high tenacity polyester filament fiber during twisting polyester or cotton staple

fibers, to get higher tensile, balancing softness of spun sewing thread and

high tensile strength, ideal for denim and fabric handbags.

Standards and Technical parameters for Sewing Thread

Core Quality Criteria of sewing

threads is sewability, it is affected by

below thread parameters:

1. Twist (TPM): Balanced primary and secondary twists

ensure smooth stitching and appearance.

2. Thread Breaking

Strength (N): Directly

impacts stitching performance.

3. Color Fastness: Dry/wet rubbing fastness must be ≥

Grade 4 to prevent fading. [1]

4. Elongation

Rate: Polyester sewing threads have lower elongation, nylon sewing threads have higher elongation.

5. Light Resistance: For some special products or outdoor goods, UV resistance

could be enhanced via post-treatment.

![]() Polyester Sewing Thread Nylon Sewing Thread Bonded Nylon 66 Thread

Polyester Sewing Thread Nylon Sewing Thread Bonded Nylon 66 Thread

![]() Core Spun Sewing Thread Sewing Thread Types and Standards

Core Spun Sewing Thread Sewing Thread Types and Standards

Ningbo Tayyon Thread Co., Ltd.

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Tel./Fax: 0086-574-88381625

Tel./Fax: 0086-574-88381625

Email: info@tayyon.com

Email: info@tayyon.com