Tel

Tel Email

EmailBonded Nylon 6.6 Sewing Thread - Application Scenarios

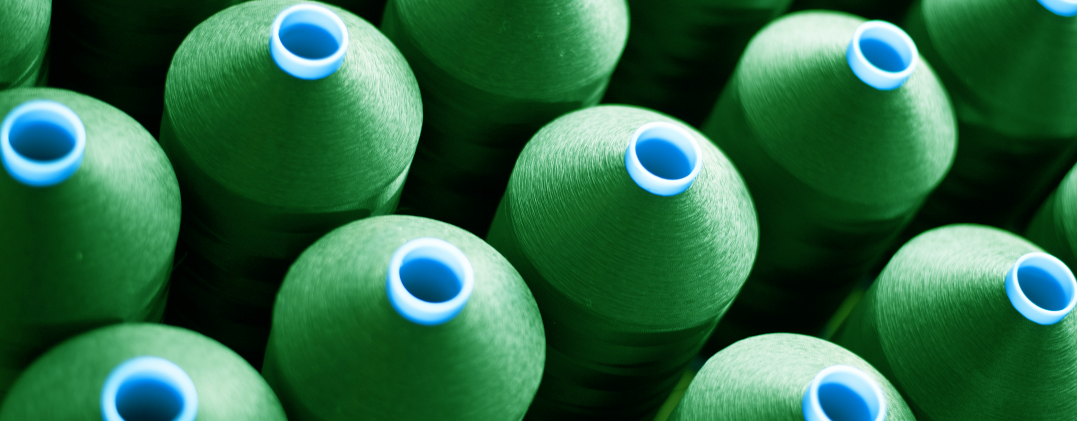

Release time:2025-03-20 Click:1567Bonded nylon 6.6 sewing thread, also called bonded polyamide 6.6 or nylon 66 sewing thread, is widely used in premium footwear, handbags, leather goods, and automotive manufacturing, making it the most versatile high-end sewing thread on the market.

Solving Sewing Challenges with Bonded Thread:

For extra-thick materials like ABS hard-shell luggage, abrasion-resistant nylon fabrics suitcase, industrial conveyor belts, automotive upholstery, and seat belts - where dense fabrics and high needle temperatures pose challenges - ordinary polyester threads often fail by fraying, unraveling, or breaking. Nylon 6.6 bonded thread is specifically engineered for these demanding applications. Using tenacity 8.5 grams per denier heat-resistant nylon 66 filaments bonded through proprietary Bonded technology, this triple-ply thread delivers exceptional tensile strength, heat resistance, and abrasion resistance. Its fused structure maintains integrity through needle eyes, preventing fraying and puckering even on ultra-thick, rigid materials.

Dual-Needle Sewing Solutions:

Dual-needle stitching presents unique challenges as one thread follows reverse needle rotation, causing untwisting (particularly problematic with standard S-twist/Z-twist threads). This leads to inconsistent tension, fraying, knotting, and breakage. Bonded thread resolves this through its innovative construction: A low-melt thermoplastic core is integrated during twisting, creating a permanently fused multi-filament structure after heat setting. This bonding design enables both threads to function as unified strands through the needle, eliminating untwisting and strand separation. As the optimal solution for dual-needle operations, bonded thread ensures uniform tension and flawless stitch formation.

![]() Bonded Thread Applications Bonded Nylon 6.6 Sewing Thread Nylon 66 Bonded Thread

Bonded Thread Applications Bonded Nylon 6.6 Sewing Thread Nylon 66 Bonded Thread

![]() High Tenacity Filament

High Tenacity Filament

Ningbo Tayyon Thread Co., Ltd.

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Tel./Fax: 0086-574-88381625

Tel./Fax: 0086-574-88381625

Email: info@tayyon.com

Email: info@tayyon.com