Tel

Tel Email

EmailPly Number of Polyester & Nylon Sewing Thread

Release time:2025-04-15 Click:1156

3 Ply Filament Polyester Sewing Thread

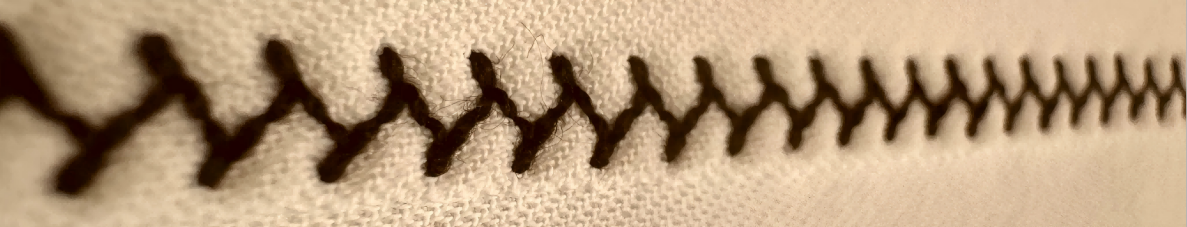

The spatial trajectory of fibers in plied polyester and nylon sewing thread is more complex than in single yarn. As sewing threads require twisting, the inclination angle of fibers relative to the axis of the plied thread varies depending on the position of individual yarns within the ply. Consequently, the configuration of fibers in plied thread is typically studied at the single-yarn level, focusing on the arrangement of each yarn in different plied structures.

When twisting 5 or fewer single yarns simultaneously, the tension distribution among yarns remains uniform during twisting. This process forms a hollow structure, resulting in uniform stability and high strength in the plied sewing thread. However, when twisting 6 or more single yarns at once, one or more yarns occupy the central position. During twisting, uneven tension distribution occurs: outer yarns experience higher tension than central ones. This tension imbalance causes positional slippage between inner and outer yarns, destabilizing the ply structure. Consequently, the plied thread develops an uneven solid structure, compromising its strength.

At higher twist levels, exacerbated tension non-uniformity may induce a spiral structure in the plied sewing thread, further degrading quality. Therefore, in practical production, the number of single yarns twisted simultaneously should not exceed 5. For applications requiring more yarns, secondary or multiple twisting processes must be employed.

![]() Ply Sewing Thread Bonded Nylon 6,6 Thread Filament Polyester Sewing Thread

Ply Sewing Thread Bonded Nylon 6,6 Thread Filament Polyester Sewing Thread

Ningbo Tayyon Thread Co., Ltd.

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Tel./Fax: 0086-574-88381625

Tel./Fax: 0086-574-88381625

Email: info@tayyon.com

Email: info@tayyon.com