Tel

Tel Email

EmailSewing Threads and Technical Yarns: Applications in the Automotive Sector

Release time:2025-04-17 Click:1091

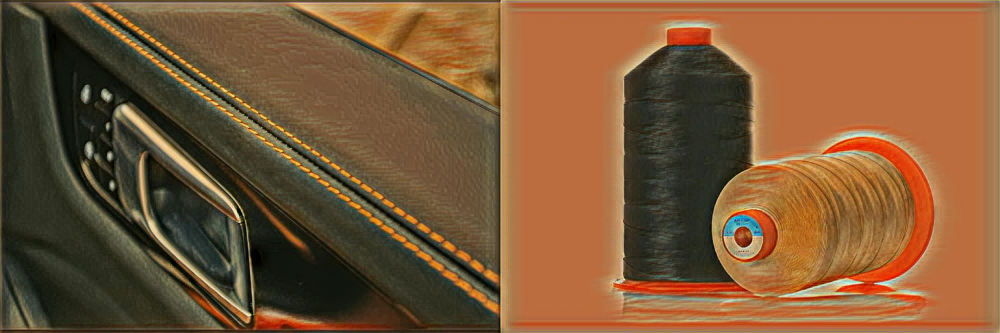

Bonded Nylon 66 Thread for Automotive Interiors Sewing

Bonded nylon 66 thread (Polyamide 6.6) or high-strength polyester bonded thread are widely used in automotive interiors, such as stitching car seats, armrests, headrests, steering wheels, as well as dashboard and door panel upholstery. Thanks to their exceptional resistance to friction, corrosion, and aging, along with non-filament-separating and resistance to breakage, in this kind of environments like car interior where subject to frequent human activity, they have largely replaced traditional non-bonded high-strength threads.

Nylon cord fabrics made from high tenacity filament nylon industrial yarns in tire reinforcement absorb impact forces during tire operation, exhibiting excellent abrasion resistance and tear resistance. Their good heat tolerance allows them to partially withstand the heat generated during driving.

Fine-denier nylon 66 industrial yarns are commonly utilized in airbags and seat belts. With the rise of new materials, aramid yarns, with their superior strength-to-weight ratio, are gradually increasing their application share in these components. Aramid-based airbags and seat belts rapidly deploy during collisions, withstand immense tension, securely restrain occupants, effectively disperse impact forces, and significantly reduce injury risk.

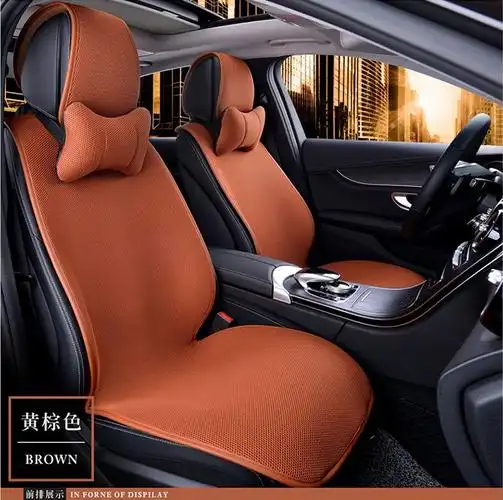

Cool Feeling Yarn Seat Cover

Increasingly, seat manufacturers are switching to acrylic yarn-based seats instead of leather to enhance comfort. Acrylic fibers offer excellent softness for a pleasant tactile experience. Their moisture absorption alleviates stuffiness and humidity during spring and summer.

Interior components: Nylon 6 bulk yarns, known for their light weight, good elasticity, high toughness, excellent thermal insulation, strong electrical insulation, abrasion/corrosion resistance, and low maintenance costs, are extensively used in carpets, headliners, and other interior parts. Products like tufted carpets, floor mats, center console side guards, and trunk lid panels made from it are durable and enhance the vehicle's interior ambiance.

PVC/PET core-sheath composite yarns are used to create automotive floor mats. This unique structure offers advantages like customizable trimming for perfect vehicle fit, eco-friendly materials free of odors and formaldehyde, exceptional wear resistance, easy cleaning, comfortable feel, fire retardancy, and anti-slip safety, providing an enhanced user experience.

To meet the demands of new energy and smart vehicles, yarn innovations have emerged. Fibers incorporating silver-plated or stainless steel filaments, wrapped around wiring harnesses or circuit boards, create EMI-shielding fabrics. These effectively block electromagnetic interference, preventing signal disruption between electronic devices and ensuring stable operation of automotive electronic systems.

Conductive yarns are replacing traditional insulated wires in internal automotive cables. They offer good conductivity and flexibility for efficient current transmission while reducing weight and stiffness, enhancing electrical system efficiency and reliability. Embedded as sensors in seats or steering wheels, conductive fibers can monitor occupant vital signs (e.g., heart rate, blood pressure) and detect posture/grip force, enhancing safety. These yarns are poised to become integral to automotive low-voltage systems.

Moisture-regulating yarns, used in air vents or cabin air filters, automatically absorb or release moisture based on cabin humidity levels, optimizing comfort. Antimicrobial and antiviral yarn fabrics, meeting rising health demands, are used in air filters to inhibit bacteria/mold growth (reportedly >99% inhibition rate), prevent odors, and ensure clean, healthy cabin air.

Luminescent fibers enable illuminated interiors, ambient lighting, ornamental dashboard items, decorative rugs, mats, and even "starry sky" effects on headliners or seatbelts. At night, this unique lighting creates a tech-savvy and romantic atmosphere, offering a distinctive driving environment.

Beyond passenger cars, high-strength industrial nylon and polyester yarns are equally vital in trucks, construction vehicles, and special vehicles. Their outstanding tensile strength, flexibility, and corrosion resistance make them suitable for cargo nets, tarpaulins, storage bags, and partition nets.

The application scope of textile threads and yarns in the automotive industry is vast. Leveraging their unique properties, diverse yarn types play critical roles across vehicle components – from enhancing safety to improve comfort, from optimizing aesthetics to enable intelligent functionality. Threads and yarns, as one branch of the very traditional industry textile , are making very important, though often not highlight, contributions to human industry and daily life.

![]() Automotive Applications Bonded Nylon 6.6 Threads Technical Yarns Textured Threads

Automotive Applications Bonded Nylon 6.6 Threads Technical Yarns Textured Threads

Ningbo Tayyon Thread Co., Ltd.

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Beicun, Dongwu Town, Yinzhou District, Ningbo City, Zhejiang Province, China

Tel./Fax: 0086-574-88381625

Tel./Fax: 0086-574-88381625

Email: info@tayyon.com

Email: info@tayyon.com